DESCRIPTION

Live centers are tools used to support and stabilize a rotating workpiece during machining on a lathe. Unlike static centers (dead centers), live centers feature bearings that allow them to rotate along with the workpiece, reducing friction and wear.

Design and Construction:

Consist of a tapered tip that fits into the center hole of the workpiece.

Include high-precision bearings for smooth rotation.

The body is often made of high-strength steel or other wear-resistant alloys.

Cone Shapes and Types:

Available with various cone angles (commonly 60°) depending on the application.

Some models feature replaceable tips or specialized profiles for specific machining tasks.

Mounting Types:

Live centers have a shank that fits into the lathe tailstock or turret, typically with a standard taper (e.g., Morse Taper).

Applications:

Support for Large or Long Workpieces:

Used to support shafts, pipes, or parts that require stability during rotation.

Precision Machining:

Prevent vibrations or bending, ensuring accurate machining.

High-Speed Operations:

Ideal for applications requiring high cutting speeds without excessive heat or wear.

Specialized Machining:

Certain live centers are designed for specific tasks, such as supporting pipes or holding tapered surfaces.

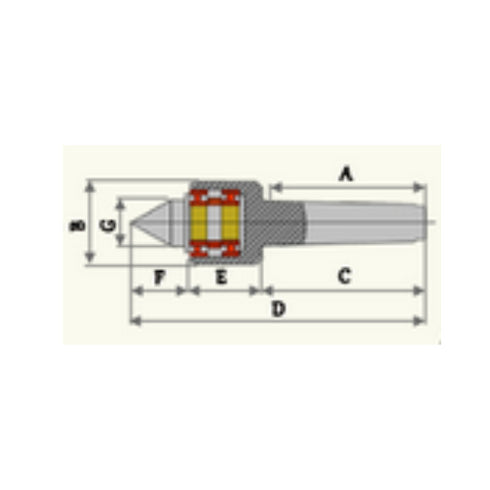

Dimension Explanation: Cone / C x G x F (mm)