Races Are Won in the Pit Stop: How the EWS VARIA System Transforms Tool Changeovers

Races are won in the pit stop.

The same principle applies to a modern machine shop.

Tool setup and changeover times have a major impact on the performance of both turning and milling operations. Reducing production time is directly linked to lower manufacturing costs, a fact well known to professionals involved in metal cutting and machining processes.

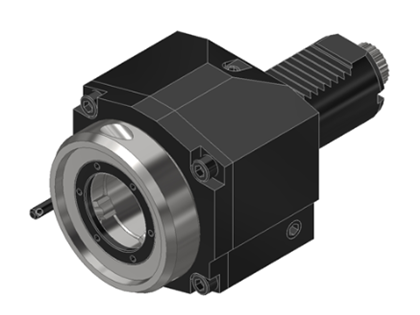

This is exactly where the VARIA quick-change tool system by the German manufacturer EWS makes the difference.

The VARIA system consists of various tool holding adapters, including:

-

collets

-

Weldon holders

-

shrink fit

-

hydraulic collets

and more, which lock directly into a lathe toolholder, whether driven or static.

Thanks to its one-hand adapter change mechanism, VARIA allows a complete and safe tool change in just 20 seconds. No force required, no wrenches, and no unnecessary downtime.

With EWS VARIA, tool changes become fast, simple, and reliable, boosting productivity, minimizing idle time, and turning your machine shop into a true high-performance pit stop.

SHARE: